Available Now

High-Integrity mRNA & saRNA

in Hours, Not Days

Meet NTxscribe®, the automated, continuous flow platform transforming RNA synthesis

Go from DNA template to 50mg* purified, high-quality mRNA or saRNA in just 3 hours. Accelerate your research and development with unprecedented speed, scalability, and benchtop accessibility.

*Output varies based on template size, typical range is 40-65mg

Automated, Continuous-flow RNA Synthesis & Purification

To support the growing demand for mRNA based vaccines and therapeutics, NTx has developed a first of its kind, proprietary continuous-flow, in-vitro, transcription system utilizing hollow fiber bioreactors. This biosynthetic process provides a low cost and rapidly deployable vertically integrated manufacturing system. This system allows for manufacturing scale from milligram R&D quantities to large scale commercial needs all in a small, economical footprint, with the supply of critical enzymatic components secured by NTx.

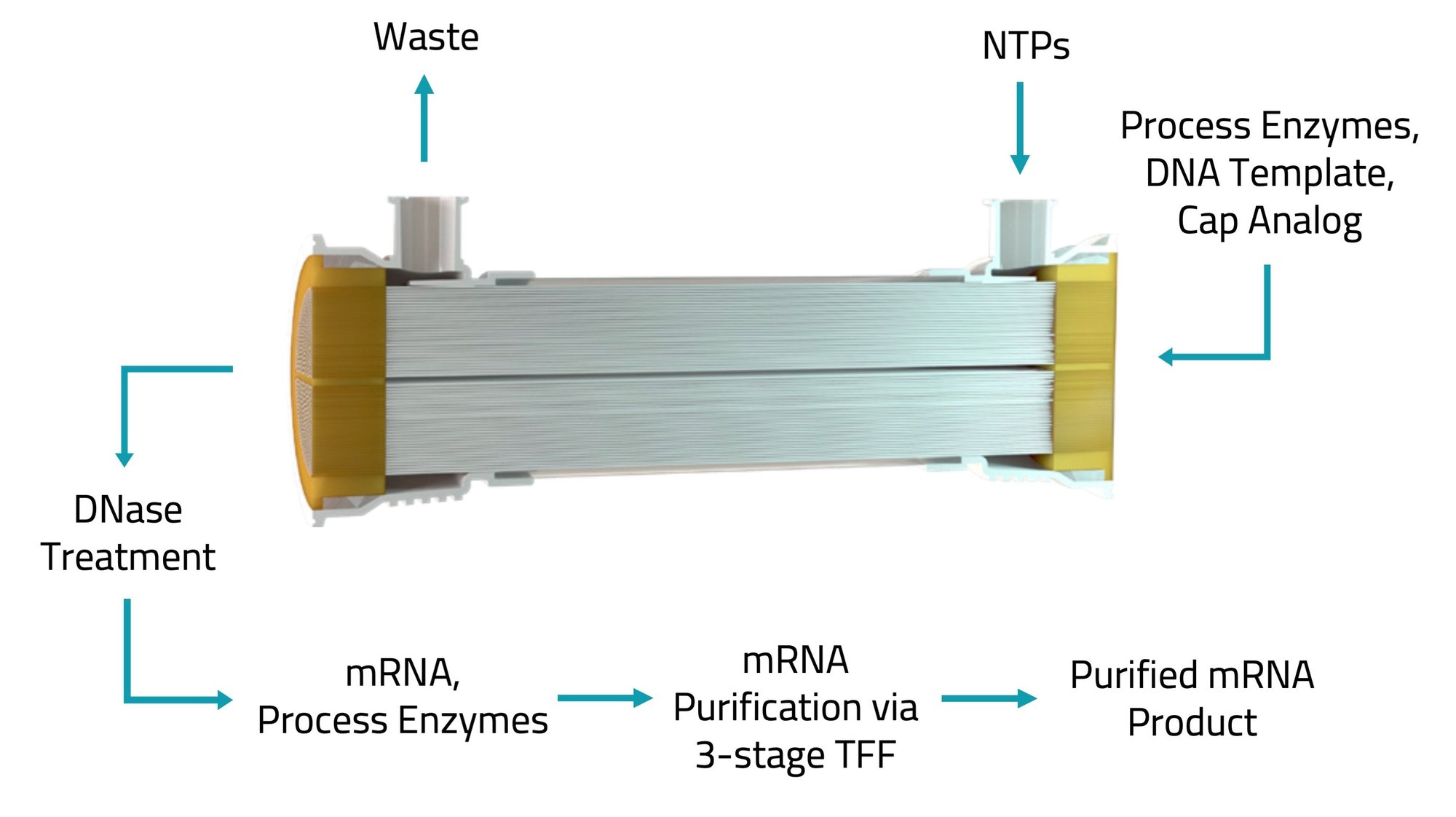

In our standard workflow, 5’-capping of the mRNA is accomplished co-transcriptionally in continuous flow (directly coupled mRNA synthesis).

This unique approach minimizes handling of the material in between production steps, prevents damaging the molecules and ensures integrity, incorporates a purification process that improves yields, and can be scaled up linearly using the same process from discovery through product commercialization, saving valuable time.

NTxscribe® Process (IVT + Purification)

The Principal Advantages of NTxscribe® Include:

-

Higher Productivity, Smaller Footprint – Continuous processing delivers greater throughput with lower scale requirements than traditional batch methods.

-

Superior RNA Quality – Short residence time in the bioreactor preserves RNA integrity and minimizes dsRNA formation, easing downstream purification.

-

Sterile, Single-Use Design – Closed, disposable system configuration maintains product sterility and reduces contamination risk.

-

Gentle Process Conditions – Lower shear and limited handling minimize RNA degradation.

-

Operational Efficiency – Streamlined workflow reduces batch steps and simplifies manufacturing.

-

Scalable Performance – Enables seamless linear scaling from milligram to gram quantities.

-

Process Intelligence – Integration of real-time process monitoring, with capability to add in-line analytical monitoring for enhanced control.

Producing Conventional and Self-Amplifying mRNA

NTxscribe® consistently delivers high-quality RNA across a broad range of transcript sizes, from standard mRNA to challenging self amplifying RNA (saRNA). Our continuous flow technology excels where batch methods often struggle, preserving the integrity of long and sensitive molecules. Whether you’re optimizing vaccine candidates or developing novel therapeutics, trust NTxscribe® to reliably produce the high-integrity RNA essential for your success.

-1.png?width=2000&name=DSC09974-1-B%20(2)-1.png)