Our Platforms

Redefine Biomanufacturing

NTx is enabling access to tomorrow’s

therapeutics, today.

Accelerate your breakthroughs with NTx Bio’s continuous flow platforms. We eliminate the manufacturing bottlenecks inherent in conventional RNA and protein synthesis, putting high-quality manufacturing on any benchtop to enable faster development cycles and seamless scaling. Our technology provides the agility and efficiency needed to bring tomorrow’s therapies to reality, today.

How NTx is Revolutionizing Biomanufacturing

Conventional Batch Process Manufacturing

Cost $Bs to build a manufacturing plant

- Conventional plants built for volume

- Smaller liquid handling systems cannot deliver scale

Requires significant process development (days to months) and retrofit for each “batch”

- Static process

- Cannot be easily distributed or mobilized

NTx Continuous Flow Process Manufacturing

Cost

Small, low-cost footprint that delivers high yield, high integrity mRNA

Scalability

- Consistent process from discovery through clinic

- Linear scaling from personalized doses to public health response

Speed

Hours. Rapid set-up and minimal development

Agility

Fully-closed compact system can be deployed to any bench anywhere, enabling production at the point-of-care

Reinventing Biomanufacturing to Improve Care

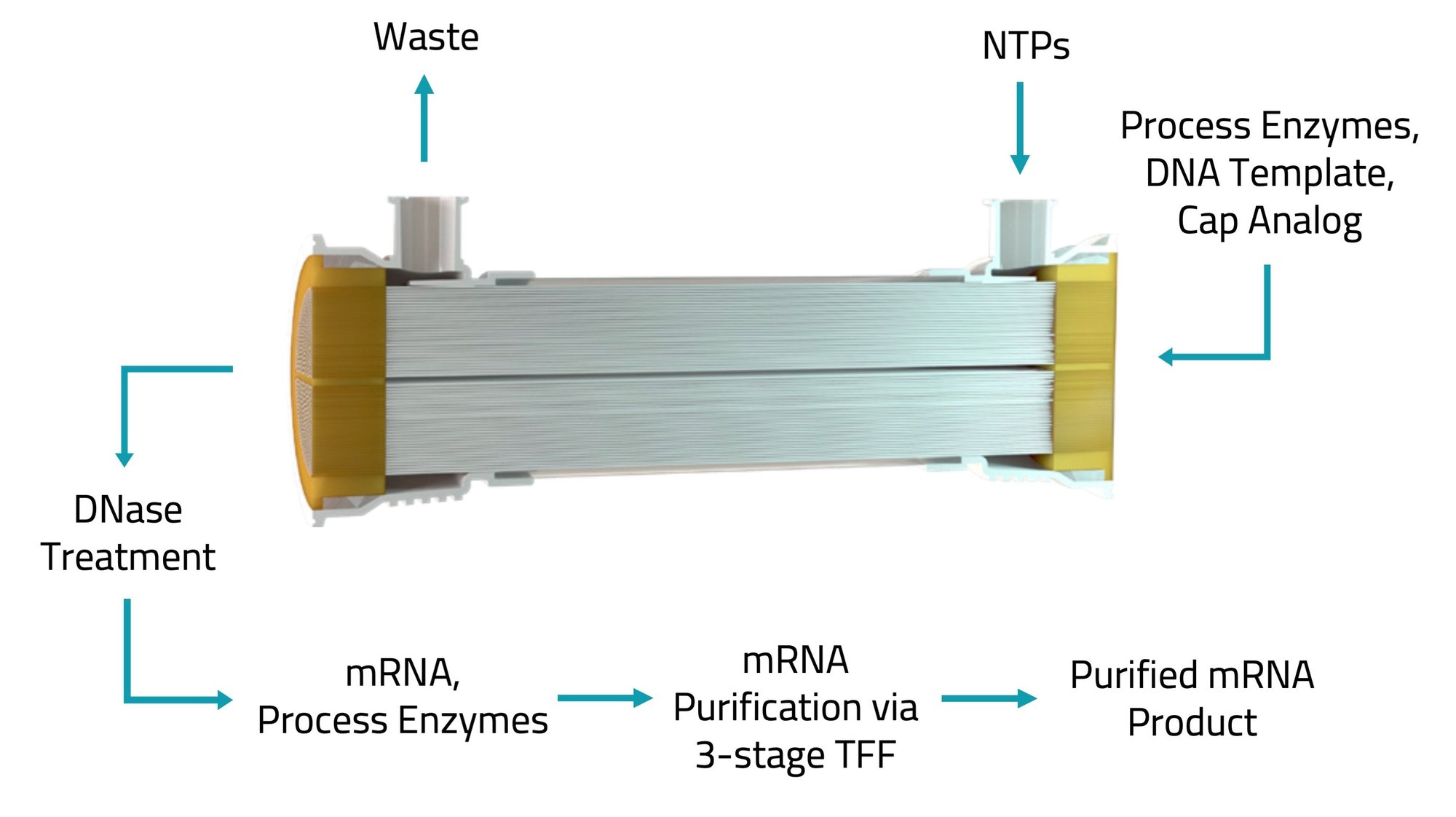

NTxscribe® Process (IVT + Purification)

-

Higher Productivity, Smaller Footprint – Continuous processing delivers greater throughput with lower scale requirements than traditional batch methods.

-

Superior RNA Quality – Short residence time in the bioreactor preserves RNA integrity and minimizes dsRNA formation, easing downstream purification.

-

Single-Use Design – Closed, single-use system configuration reduces contamination risk.

-

Gentle Process Conditions – Lower shear and limited handling minimize RNA degradation.

-

Operational Efficiency – Streamlined workflow reduces batch steps and simplifies manufacturing.

-

Process Intelligence – Integration of real-time process monitoring, with capability to add in-line analytical monitoring for enhanced control.